RVS Technology

RVS Technology integrates with the original surface creating a mirror-like Triboceramic surface on the metal friction zones of engines, gearboxes and other mechanical items. As a result, a worn mechanism is restored to near or original specification due to friction decreasing with tolerances and compression restoring to, or close to original specification.

- Prolongs life cycle of components (30–70 %)

- Reduces replacement demand for costly spare parts as wear process almost stops

- Reduces the number of expensive downtimes and maintenance hours/days

- Improves predictability of mechanism function

- Reduces energy & fuel consumption (5–10 %)

- Reduces emissions – Reduced environmental strain (10–30 %)

- Reduces vibration & noise level (10–50 %)

- Reduces need/Prolongs life cycle of lubricants (30–50 %)

- Possibility to use less expensive lubricants with fewer additives

- Fewer corrosion problems

- Survival of the mechanism in case of accidental loss of lubricant!

UP TO

5-15%

Increase Power

UP TO

5-10%

Lower Fuel Consumption

UP TO

50%

Longer Engine Life

UP TO

30%

Decreased Emissions

PATENTED TRIBOCERAMIC NANOTECHNOLOGY

BREAKING DOWN FRICTION

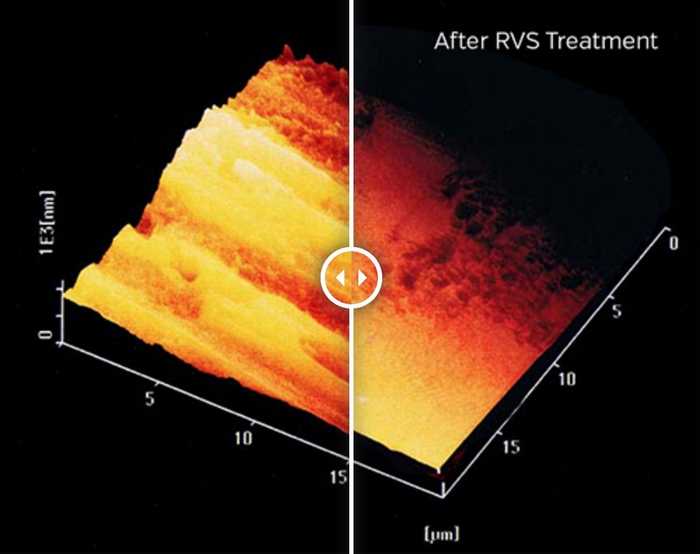

Building new material, not polishing! RVS Technology treatment grows new surface material to all those friction surfaces that are in contact with the oil. The metal ceramic surface is formed only in the areas in which there is friction and the abrasion occurs only in those areas where the surface has breaking peaks in the surface. In addition, the new surface created is much harder and smoother than the original. Seen here is a laser microscope image of a camshaft before and after RVS Technology treatment.

I performed an RVS treatment to my classic Morris Minor Traveller. I have noticed it is now easier to start and there is more power. The local hill that I had to take in 2nd gear is now easily going up in 3rd gear! Great result

Keith W. West Sussex

Step 1

Add half of the RVS mixture

to a warm engine

Step 2

Let your engine idle

for 15 minutes

Step 3

Add remaining RVS mixture

and drive for 30 minutes

FAQ

Frequently Asked Questions

What exactly is RVS Technology®?

RVS Technology® Tribo (nano-) Ceramics can be considered as an advanced cure for engines, gearboxes, and other mechanisms. If your machine has normal wear problems like noise, smoking, high fuel/oil consumption, a decrease in power and compression level, unbalance and vibrations RVS Technology has the capacity to restore it. RVS Technology works also as a preventive method, protecting your mechanisms against coming wear. For example treatment of car parts will protect your car from serious problems in the future.

What does RVS mean?

Restores Vital Surfaces

Is RVS an oil additive?

No! Unlike oil additives on the market, RVS Technology® products produce a nano-ceramic layer that integrates with the metal friction surfaces of your engine, transmission, differential etc. That’s why it lasts at least 100,000 km (60,000 miles) and oil changes do not affect it. RVS does not affect the properties of the oil. The idea of oil additives is to improve the oil properties and they have to be re-applied at every oil change.